People often wonder how to select the best air purifier for their needs. There is a lot of information out there, and it can be hard to make sense of it all. The Blueair Performance Book provides you with hard facts about indoor air pollution and Blueair air purifiers – from performance, energy efficiency and noise levels, to pollutant removal, quality and safety standards.

Some pollutants of concern indoors include:

· Combustion byproducts such as carbon monoxide, particulate matter and environmental tobacco smoke

· Substances of natural origin such as radon and pet dander

· Biological agents such as molds

· Pesticides, lead, and asbestos

· Various volatile organic compounds (VOCs) from a variety of products and materials

Health effects associated with indoor air pollutants include:

· Irritation of the eyes, nose, and throat

· Headaches, dizziness, and fatigue

· Respiratory diseases including asthma and allergies, heart disease and cancer

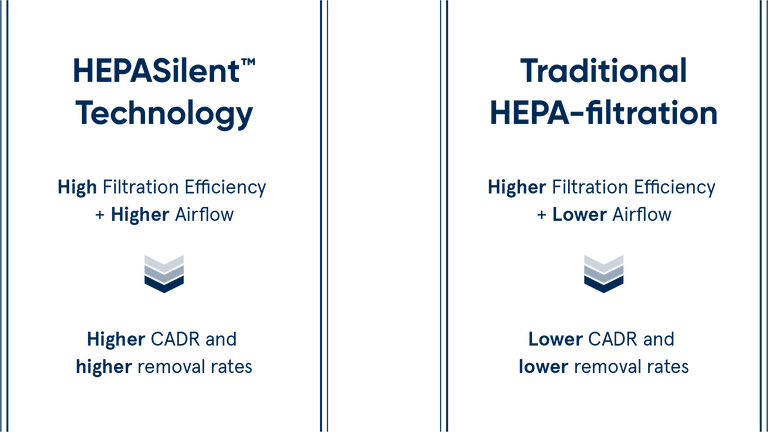

Blueair’s air purifiers use either the trademarked HEPASilent™ or HEPASilent Ultra™ filtration technologies. Both technologies combine two types of particle filtration methods, electrostatic and mechanical, resulting in an overall filtration efficiency superior to either technology alone. Due to this combination, Blueair’s air purifiers are able to use less dense filters, resulting in a high airflow and thereby a high Clean Air Delivery Rate (CADR). Less dense filter media and high airflow also result in lower noise levels and energy consumption.

What makes Blueair air purifiers unique is the proprietary Blueair HEPASilent™ technology. By combining electrostatic and mechanical filtration, the HEPASilent™ technology ensures that a Blueair air purifier delivers maximum filtration with minimum noise and energy.

Comparative tests between the HEPASilent™/HEPASilent Ultra™ technologies and conventional mechanical filtration were performed at the Blueair Test Center in Stockholm, Sweden. Particle CADR according to standard GB/T 18801- 2015, noise levels according to ISO 3743 and energy consumption where first tested on HEPASilent™ Technology set up. Identical tests where then performed on the same set up but with only mechanical filtration enabled. The tests showed that the particle CADR was more than 56% higher when the HEPASilent™ Technology was activated compared to when it was disabled.

The tests also proved that in order to achieve the same CADR without the electrostatic filtration, the fan speed needed to be increased significantly. The results from the test showed that the HEPASilent™ Technology consumed 75% less energy and kept the noise level 13dB lower while delivering the same amount of clean air as mechanical filtration alone.

The HEPASilent Ultra™ Technology, Blueair’s most advanced filtration technology ever, is developed for the HealthProtect™ series and incorporates new innovations to improve the efficiency and performance achieved by the HEPASilent™ technology even further.

Similar to the HEPASilent™ Technology, the HEPASilent Ultra™ technology combines mechanical and electrostatic filtration to achieve a high performance. The unique fan technology in the HEPASilent Ultra™ is developed in Sweden by Blueair’s engineering team to ensure that it is optimized to the rest of the system, resulting in high-capacity air distribution and allowing a compact build. The electrostatic filtration used in the HEPASilent Ultra™ technology, is placed in the very outlet of the fan, creating a threedimensional charging barrier that all the air passing through the unit interacts with. The charging barrier ensures that even more particles are charged, which increases the filtration performance. In fact, the HEPASilent Ultra™ technology has been verified to remove particles down to 30 nanometers in size and deliver more clean air, less energy and less noise compared to conventional mechanical filtration technologies such as H13/True HEPA-filtration.

Finally, the HEPASilent Ultra™ technology is the first filtration technology from Blueair that, besides the mechanical and electrostatic filtration, is developed to incorporate activated carbon to remove gases and odors from the air.

Comparative tests between the HEPASilent Ultra™ technology and mechanical filtration with a HEPA H13 filter were performed at the Blueair Test Center in Stockholm, Sweden. Particle CADR according to standard GB/T 18801-2015, energy consumption and noise levels according to ISO 3743 where first tested on a unit in the HealthProtect™ 7400 series, considered to be representative of the elements used in the HEPASilent Ultra™ technology. Identical tests where then performed on the same HealthProtect™ 7400 unit but with the electrostatic filtration turned off and the original, Blueair Smart Filter replaced by a custom, appropriately sized HEPA H13 filter.

The test showed that the particle CADR was more than 54% higher when using the HEPASilent Ultra™ technology compared to only using a HEPA H13 filter. The tests also showed that in order to achieve the same CADR with the HEPA H13 filter, the fan speed needed to be increased significantly. The results from the test showed that the HEPASilent Ultra™ Technology consumed 42% less energy and kept the noise level 4,5dB lower while delivering the same amount of clean air as mechanical H13/True HEPA filtration alone

CADR is measured in cubic feet per minute (cfm), or cubic meters per hour (m3/h) and indicates how much clean air is delivered by the air purifier and how well the system removes impurities from the air. Clean Air Delivery Rate can be measured for both particles and gases. CADR is the most common performance indicator for air purification performance and is included in widely used and recognized standards both globally and locally.

Why CADR matters

A consumer doing research on what air purifier to buy, will come across a number of different performance indicators and might have a hard time making a decision. Filtration efficiency, or “single pass efficiency” as it is sometimes referred to, is a commonly used metric, but it is important to note that filtration efficiency alone is not a good measurement for an air purifier’s actual performance. Filtration efficiency only shows the performance of the filter but does not say anything about the air purifier’s overall ability, speed or capacity to remove the pollutant in the room. Focus instead needs to be on the combination of the air purifier’s filtration efficiency and the airflow that the unit can deliver. This is exactly what CADR measures.

CADR takes the complete air purification system into consideration rather than just looking at the filter’s efficiency or the fan’s ability produce airflow. To achieve a high CADR rating both the filtration efficiency of the air purifier and its airflow needs to be optimized to clean the air quickly and effectively from pollutants.

The HEPASilent™ and HEPASilent Ultra™ technologies are developed to achieve a high CADR by focusing on achieving a high filtration efficiency while still allowing a high airflow through the air purifier. Traditional filtration technologies, such as HEPA filtration, often achieves a high filtration efficiency, but the dense filters needed to achieve the filtration efficiency limits the airflow through the filter resulting in a lower CADR.

CADR makes it easier for consumers to compare the performance of different air purifiers tested according to the same method or standard and makes it easier to avoid air purifiers that only have a high filtration efficiency or a high airflow.

There is a wide range of methods and standards for measuring and calculating the CADR of an air purifier. Some methods focus on particle removal and some on removal of gaseous pollutants, while some measure both. The different methods may result in different CADR values.

Blueair products are tested according to various globally and locally used CADR standards. In China, tests on formaldehyde, VOC’s and tobacco smoke are used to determine the CADR values. Potassium chloride (PM0.3) is measured in Korea. Dust and tobacco smoke is tested in Japan, and the Association of Home Appliance Manufacturers (AHAM) use tobacco smoke, dust and pollen to determine the CADR for different sizes of pollutants.

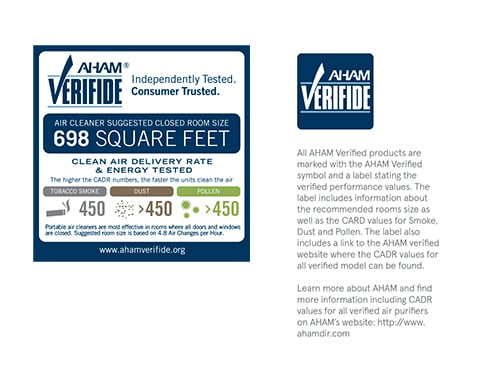

The AHAM Verifide Program is an independent air purifier verification program of the Association of Home Appliance Manufacturers (AHAM) that aims to ensure that performance testing results for air purifiers are accurate and impartial. The program has become a globally respected performance indicator for air purifiers and is used by many leading air purifier manufacturers. Blueair is one of the member companies of AHAM and our air purifiers are tested according to the latest standards.

AHAM requires CADR tests and room size calculations to be performed in accordance with the ANSI/AHAM AC-1-2019 standard, which is the only air purifier standard recognized by the American National Standards Institute, ANSI. The standard specifies how the CADR of an air purifier is tested and how the results are converted to a suggested room size. When this is done, the air purifier can be marked with the AHAM Verifide Seal. Blueair units carry this seal, proving that they are accurately tested. The seal also makes it easier to see information about the unit’s performance and suggested room size.

AHAM requires CADR tests to be performed for tobacco smoke, dust and pollen. Smoke represents particles in the 0.1-1 μm range, while dust particles fall between 0.5-3 μm and pollen particles between 5-11 μm in size. The maximum CADR values that may be claimed according to the ANSI/AHAM AC-1-2019 standard, is 600 cubic feet per minute (cfm) for cigarette smoke and dust and 450 cfm for pollen.

All AHAM Verifide models and their performance can be found in the online AHAM Verifide database.

Blueair units are designed for use in all types of indoor environments, from small bedrooms to large open areas. The basic task of an air purifier is to remove the pollutants from the indoor air faster than they enter. To achieve this, it is necessary to choose a unit suitable for the size of the room where it is to be used.

In normal indoor situations polluted air is constantly added to the room through indoor sources, ventilation, or poorly sealed windows. An easy way to find out if an air purifier has the capacity to keep the air in the intended room constantly clean is to look at its recommended room size. In general, an air purifier with a higher clean air delivery rate will be able to clean a larger room than an air purifier with a lower clean air delivery rate.

According to ANSI/AHAM AC-1 2019, the recommended room size is based on the assumption that an air purifier operating in a room with the recommended room size will be able to reduce the concentration of indoor pollutants by 80% and continue to keep the pollutant concentration at this level even with the influx of unfiltered air from ventilation, indoor pollutant sources etc. For the air purifier to be able to keep up with unfiltered air entering a room with the recommend room size, the air purifier must deliver an amount of clean air (CADR) sufficient to exchange all the air in the room approximately 4.8 times per hour (4.8 ACH).

In ANSI/AHAM AC-1 2019, the room size recommendation (in square feet) is calculated from the air purifier’s CADR, using the following formula:

Recommended Room Size (sqft) = CADR (for smoke) x 1.55.

The room size can be converted to square meters with the following formula:

Recommended Room size (m²)=0,093 x Recommended Room size (ft²)

When comparing air purifiers from different manufacturers, make sure that the recommended room sizes are comparable and most importantly that the stated room size is specified at the same ACH. An AHAM verified air purifier will always deliver 4.8 air changes per hour, based on the recommended room size.

In some cases, it might be necessary to recalculate the recommended room size in order to compare different air purifiers. If the air purifier’s smoke CADR (in cubic feet per min) is known, the below formula can be used to calculate the recommended room size (according to ANSI/AHAM AC-1-2019, in square feet) based on different number of air changes per hour. The formula assumes that the ceiling height in the room is 8 feet.

Recommended Room Size= (CADRsmoke x 60)/(ACH x 8)

Even if it is possible to recalculate the recommended room size based on different number of Air Changes per Hour, it is important to note that a larger recommended room size based on a lower number of air changes per hour, might actually not be able to lower the pollutant concentrations effectively due to influx of polluted air.

If the air purifier is placed in a room larger than it is recommended for, the number of air changes per hour (ACH) will be reduced and the air quality will be affected negatively since the amount of cleaned air will not be sufficient to keep up with the influx of polluted air. The opposite applies if an air purifier is used in a room smaller than the recommended room size where the air quality will improve due to the high amount of clean air delivered.

Blueair has choose to follow the AHAM guidelines in making room size recommendation according to 4.8 air exchanges per hour.

The below chart shows how the particle levels in a room are affected by the number of air changes per hour (ACH) provided by the air purifier. The chart is generated based on the assumption that one room volume (1 ACH) of polluted air is added to the room every hour and a room size based on the unit’s smoke CADR according to ANSI AHAM AC-1 2019.

The graph shows that the particle levels, compared to a room without an air purifier, are reduced by approximately 50% with one air change per hour, or 1 ACH. With 4.8 ACH, the particle level is down approximately 80% compared to a room without an air purifier.

The Blueair air purifiers include a wide range of solutions and technologies to ensure that the air distribution to and from the air purifier is as good as possible.

- Intake + Outlet – For example used in the Classic, Pro and Sense+ ranges, utilizes the traditional set up where air is drawn into the air purifier via the intake on one side and exited from the air purifier through an outlet on the opposite side or on the top of the unit. This has the benefit of allowing the air purifier to be placed closely against a wall. 360-degree intake + Outlet – The models in the Blue range, draw in polluted air from all directions with

- a 360-degree intake and delivers the cleaned air through the top of the unit. This allows for big filters that can filter out more pollutants. The 360-degree intake additionally offers more freedom in where the air purifier can be placed, including corners.

- The patent pending SpiralAirTM technology, used in the HealthProtectTM air purifiers, focuses on the distribution of air from the air purifier and ensures that clean air is circulated to every corner of the room. The uniquely designed outlets, wrapped around the air purifier’s edges, offers 360-degree omni-directional airflow that makes it possible to place the air purifier anywhere in the rooms while still getting optimal clean air coverage.

Particulate matter, or PM, is the term for a mixture of solid particles and liquid droplets found in the air, whose major components are black carbon, sulfate, nitrates, ammonia, sodium chloride, mineral dust, and water. A synonym for particle matter commonly used when particles occur together with gases is aerosol.

The efficiency of a filter is a measurement of the percentage of pollutants that are removed from the air after it has passed through the filter once. The more pollutants that are removed after one air passage, the higher the efficiency.

Even if filtration efficiency, or “single pass efficiency” as it is sometimes referred to, is a commonly used metric, it is important to note that filtration efficiency alone is not a good measurement for an air purifier’s actual performance. Filtration efficiency only shows the performance of the filter but does not say anything about the air purifier’s overall ability, speed or capacity to remove the pollutant in the room. Focus instead needs to be on the combination of the efficiency and airflow that the unit can deliver. Read more about CADR here.

The HEPASilent™ family of technologies used in the Blueair products have been proven to capture at least 99.97% of particles down to 0.1 microns in size. The high filtration efficiency of the HEPASilent™ technology in combination with a high airflow thanks to the less dense filters, means that a high amount of clean air can be delivered (CADR).

In May 2017 and January 2018, tests were done at RISE Research Institutes of Sweden AB in order to verify the filtration efficiency of the HEPASilent™ technology. Two filter media used for the Blueair Classic and Pro air filters were tested with charged particles according to the method specified in the European standard EN 1822-5:2009. The results showed that the HEPASilent™ technology has a filtration efficiency of at least 99.97% for particles down to 0.1 microns in size.

Nano particles or Ultrafine particles are usually defined as particles with a size between 1 nanometer (nm) and 100 nanometers. Sources of ultrafine airborne particles include natural occurrence and different types of combustion, such as fuel combustion from vehicles, burning of fossil fuels or waste burning. Examples of nano sized airborne particles include soot, dust and viruses.

Blueair’s HEPASilent™ Technology has been tested to remove particles down to 100nm (0.1micron) and the HEPASilent Ultra™ Technology has been tested to remove particles all the way down to 30nm (0.03micron).

In November 2020 nano particle reduction tests were performed at the Life Science Research Laboratory in Koriyama, Japan. In the test, a Blueair HealthProtect™ 7770i unit was placed in a 30m3 stainless steel test chamber and Potassium Chloride particles ranging from 30-100nm in size were added to the chamber by a particle generator. The initial particle concentrations for the different particle sizes were measured. The air purifier was then run at the highest speed and the particle concentration in the chamber for each particle size was measured every 30 seconds. After 15 minutes the total nano particle concentration in the test chamber had been reduced by more than 99%.

The filtration efficiency of a system in combination with the air purifier’s airflow determines how well the unit will clean the air. Only in combination with a high airflow will a high efficiency lead to good air purification. An air purifier’s ability to remove particles is commonly specified by stating its Clean Air Delivery Rate, or CADR. The higher the CADR value, the more clean air is produced by the air purifier and the better it will be at cleaning the air in a room.

Testing and results

Blueair has performed extensive CADR and Removal rate tests on wide range of particulates such as PM2.5, pollen, mold, virus and bacteria.

See the performance data here.CADR not only indicates how much filtered air is delivered by the air purifier but is also a measurement of how fast the unit is able to remove pollutants, in the air. A unit with a high CADR will be able to clean the air in a room of a specific size faster than a unit with a lower CADR. The amount of pollutants that the unit removes during a specified period time is referred to as the unit’s removal rate (%). The removal rate is calculated by comparing the initial amount of pollutants with the amount of pollutants remaining after the specified period of time has passed. The higher the removal rate, the fewer particles remain.

Indoor air contains viruses and bacteria that can be captured by the air purifier thanks to the HEPASilent™ and HEPASilent Ultra™ Technologies. Even though these germs are small, usually around 0.02-5 micrometer, they can still be captured and removed from the air thanks to the combination of mechanical and electrostatic filtration.

In extreme conditions, bacteria inside an air purifier can start to grow. This may happen when the air purifier is used seldomly or turned off for longer periods of time.

The Blueair products include a range of technologies to prevent bacterial growth and to deactivate the captured germs.

Bacterial inactivation

While running, an air purifier with the HEPASilent™ or HEPASilent Ultra™ Technology, the combination of electrostatic and mechanical filtration has the ability to inactivate bacteria captured on the filter.

In February 2020, tests were performed at the Blueair Test Center in Mumbai, India, to verify the HEPASilent™ and HEPASilent Ultra™ Technologies’ ability to inactivate microbes on the filter. The tests were run on a Blueair Classic 280i unit and the results are considered to be representable for all models based on the HEPASilent™ and HEPASilent Ultra™ technologies.

In the tests, a unit was run for three hours at the highest speed, in a normal indoor environment with open windows to collect bacteria expected to be found in indoor environments.

The air purifier was then moved to a sterile test chamber where it was run at the highest speed for another 36 hours. After the test, the unit’s filter was analyzed and compared to a reference filter from another 280i unit collecting bacteria for 3 hours under the same conditions.

The test results showed that the number of microbes on the filter from the unit that was run for 36 hours was reduced by 99% compared to the number of microbes found on the reference filter.

The GermShield™ technology, used in the HealthProtect™ models, provides 24/7 protection against virus and bacteria when the unit is on standby. When on standby, it continues to monitor your room and kills germs and prevents growth of bacteria on the filter.

The GermShield™ technology uses Blueair patented sensor technology to detect environmental conditions such as high temperature and humidity that are favorable for germ growth. When certain environmental criteria are met, GermShield™ will automatically activate a low air flow that will dry out the germs, effectively killing them, while plasma charging, an optimized electrostatic sequence, is used to create an environment inside the air purifier that prevents further bacterial growth.

In August-September 2020, a series of test were done to verify the GermShield™ technology’s ability to inactivate virus and bacteria. The tests were done at the Guangdong Detection Center of Microbiology, China on Blueair HealthProtect™models 7410i and 7710i that were considered to be representative for all models with GermShield™ technology. During the tests, nebulized (droplets) mixtures containing MS2 bacteriophage (ATCC 15597-B1) virus and Staphylococcusalbus bacteria were released into the test chamber where the air purifier was placed. The air purifier was then turned on in order to collect the release droplets. After placing the unit in standby mode but with the GermShield™ function activated for 24 hours, the units’ filters were analyzed. The analysis showed that at least 89% of the virus and at least 82% of the bacteria were inactivated.

In December 2020 and March 2021, a series of test were done to verify the GermShield™ technology’s ability to prevent germ growth. The tests were done at the Guangdong Detection Center of Microbiology, China on all Blueair HealthProtect™ models. During the tests, nebulized (droplets) mixtures containing Escherichia coli (E-coli) bacteria were released into the test chamber where the air purifier was placed. The air purifier was then turned on in order to collect the release droplets. A control sample was collected for further analysis. After placing the unit in standby mode with the GermShield™ function activated for 36 hours, the units’ filters were analyzed and compared to the control sample take earlier. The result showed 0% microbial growth and that the microbe count on the units’ filters were more than 99.99% lower compared to the control sample.

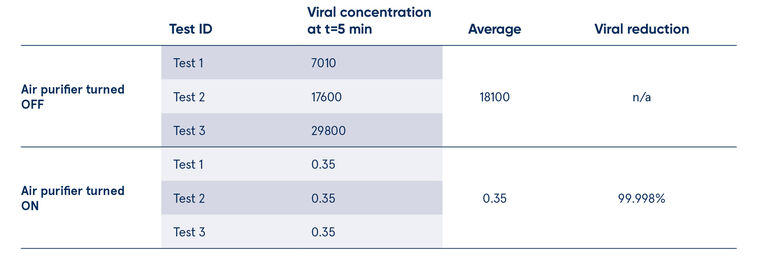

In April 2021 Blueair conducted Corona virus removal tests in a Biosafety Level 3 laboratory at MRIGlobal in Kansas City, USA. For practical and safety hazard reasons the tests were performed in a biological class III cabinet measuring 13 ft³.

A non-running Blueair HealthProtect™ 7410 air purifier was placed in the test cabinet and aerosolized SARS-COV-2 virus was released into the area. The air in the cabinet was circulated by a fan for 10 minutes to ensure an even virus distribution throughout the testing area. After the 10-minute mixing period, and with the air purifier still turned OFF, airborne virus concentration readings were taken every 30 seconds for a total duration of 5 minutes. The whole process was repeated three times. The average of the three readings at the 5-minute mark was calculated and defined as the baseline for further analysis.

The above process was repeated but with the air purifier turned ON after the fan had circulated the air for 10 minutes. Airborne virus concentration readings were again taken every 30 seconds for a total duration of 5 minutes. This was repeated three times. The average of the three readings at the 5-minute mark was calculated and compared to the baseline value with the air purifier turned OFF.

The results showed that 99.99% of the aerosolized SARS-COV-2 virus was removed from the air by the air purifier in the test cabinet.

Volatile organic compounds (VOCs) include thousands of different compounds. VOCs are organic chemicals found in both outdoor and indoor air. “Volatile” means that a compound is easily evaporated at normal temperatures and pressures.

VOC sources are widely used as ingredients in household products. Paints, varnishes and wax all contain organic solvents, as do many cleaning, disinfecting, cosmetic, degreasing and hobby products.

Irritating gases may play a role in a large number of illnesses, from respiratory disease to chemical sensitivity. A quick reduction of gaseous pollutants is best achieved by a filter with activated carbon.

Inorganic compounds are any compounds that are not organic, i e does not contain hydrocarbon groups. Examples of inorganic compounds are carbon monoxide, carbon dioxide, Nitrogen oxide (NOx) and Sulphur Dioxide (SOx). NOx is most common in air pollution. SOx is a toxic gaseous compound that results from fossil fuel combustion. Once inhaled, it can spread deep into lung tissue, causing breathing difficulties and other health problems.

Removal of gaseous pollutants

Gases are removed from the air via a process called adsorption where the gas molecules through adhesion are collected on the surface of the activated carbon in the air purifier’s filter. Even though the amount or weight of the carbon in the filter might be of importance it is not alone a measurement of the filters ability to reduce gaseous pollutants in the air. The type of carbon, the design of the actual filter and most importantly the air purifier’s airflow, will greatly affect the performance.

It is also possible to add additional components to the activated carbon to further enhance the efficiency or target specific gases.

Finally, it is worth mentioning that not all types of gases, due to their chemical properties, can be captured with activated carbon. Activated carbon also adsorbs some gases better than others.

The activated carbon in the Blueair filters is made from charcoal or from non-fossil sources such as coconut shell that have been processed to have as large surface area as possible in order to achieve a high gas removal performance and last as long as possible.

Removal rate

The amount of pollutants that the unit removes during a specified period time is referred to as the unit’s removal rate (%). The removal rate is calculated by comparing the initial amount of pollutants with the amount of pollutants remaining after the specified period of time has passed. The higher removal rate, the less gaseous pollutants remain.

Testing and results

In 2020 Blueair performed extensive gas removal rate tests on the Blue Auto and HealthProtect™ families. The tests were conducted on a wide range of gases according to standard GB/T 18801-2015 at the CVC and CAS laboratories in China.

.png?sw=768)

Most odors come from VOCs and can cause negative effects as well as unpleasant feelings. For example, strong odor has been shown to have a significantly negative effect on asthma. A quick reduction of odors is best achieved by filters equipped with activated carbon.

Deodorization performance

Deodorization performance is measured in the same way as removal rate and measures how fast an air purifier is able to remove odors from the air. It is calculated by comparing the initial amount of odors with the amount of odors remaining after the specified period of time has passed. The higher the deodorization performance, the less odors remain in the air.

Testing and results

Blueair has performed extensive removal rate tests on wide range of odors such as Ammonia, Acetaldehyde and Acetic acid.

See the performance data here.The HEPASilent™ and HEPASilent Ultra technologies used in all Blueair air purifiers allow the fan to push air more easily through the unit’s filter. This ensures a high cleaning capacity also at lower fan speeds, resulting in lower power consumption.

Naturally, air purifiers with a higher CADR, intended for use in larger areas, will have a higher power consumption than air purifiers for smaller areas. For this reason, the power consumption should always be compared to the CADR performance of the unit. A common way to compare the power consumption of different air purifiers is to look at or calculate the CADR/Watt measurement. The higher CADR/W, the better efficiency.

See the performance data here.Many countries have mandatory programs, certifications or regulations related to energy efficiency. Blueair products are tested and comply to the energy efficiency requirements in the markets where they are sold.

USA

ENERGY STAR is a program by the U.S. Environmental Protection Agency (EPA). The program was developed to help consumers save money and to protect the environment through energy efficient products. In order to obtain ENERGY STAR certification for air purifiers requirements for CADR, CADR/Watt, standby power usage and ozone emissions must be met.

Blueair was among the first air purifier manufacturers to earn the ENERGY STAR designation for all its models sold in the US and thanks to the high CADR, Blueair air purifiers significantly exceed the minimum ENERGY STAR requirements.

Only products that meet the ENERGY STAR requirements and have become certified by ENERGY STAR are allowed to bear the ENERGY STAR Logo. The logo is placed on the product packaging or on unit.

China

Chinese requirements for energy efficiency are covered in the standard GB/T18801-2015 and GB 36893. Both standards include requirements for CADR/watt and standby power.

Korea

The Korean MEPS (Minimum Energy Performance Standards) measures the efficiency of the air purifier and also requires the products to be clearly labeled with the power consumption and efficiency values.

Noise from air purifiers generally comes from the fan or motor and the air pressure through the filter. Blueair’s whisper-silent operation is a result of the HEPASilent™ and HEPASilent UltraTM filtration technologies and the use of less dense filters that allow the fan in our units to push air more easily through the filter, resulting in a high cleaning capacity while keeping the noise levels down.

When specifying an air purifier’s noise level, an A-weighted decibel value, or dB(A), is commonly used. This value indicates how the loudness is perceived by human ears. “A-weighted” means that the measurement compensates for the ear’s inability to perceive all acoustic frequencies in the same way.

It should be mentioned that the dB(A) value alone does not provide enough information in order to determine how “noisy” an air purifier is. The noise levels should always be seen in the light of the unit’s overall performance, such as CADR. The characteristics of noise, tone and how the individual subjectively perceives the noise also weigh in. Blueair puts emphasis on all these aspects during development in order to create the best overall user experience.

There are many ways to measure and calculate the amount of noise generated by an air purifier. Blueair tests and communicates both Sound Pressure and Sound Power data according to standard GB/T18801-2015. Though using the same measuring unit of dB(A), sound power and sound pressure is measured and calculated in different ways and usually differ, even for a specific model.

Please note that the many different standards and methods for measuring sound can affect the sound levels and make comparing different models and brands more complicated.

See sound performance data here.

While ozone is a molecule composed of atoms of oxygen, it should not be confused with the two-atom oxygen molecule (O2) that we breathe to support life. Ozone, which connects three oxygen atoms (O3) can decrease lung function and cause health effects such as chest pain, shortness of breath, throat irritation and increase the risk of respiratory health problems.

Though the HEPASilent™ and HEPASilent Ultra technologies uses electrostatic filtration to capture and remove particles from indoor air, Blueair air purifiers should not be associated with dangerous indoor ozone that could be formed by electronic air purifiers or air cleaning techniques based on only ionization, bi-polar ionization or by systems using ozone to clean the air. Since many customers are concerned with the negative effects of ozone, Blueair takes this matter seriously and is committed to making sure that our air purifiers are safe and do not add ozone to the room.

Blueair’s products are tested to verify their ozone reducing capabilities at the RISE Research Institutes of Sweden AB, in Borås, Sweden. The tests are done in a closed space where an ozone generator is used to create high ozone concentrations. The air purifier is then turned on and the ozone concentration at the air purifier’s inlet is compared to the ozone concentration at the outlet. The tests showed that the air, after passing through the air purifier’s filter, had up to 75% lower ozone concentrations compared to the surrounding air.

While the ozone reduction was confirmed for all tested Blueair air purifiers, the results were most obvious for air purifiers equipped with filters including activated carbon. The design of the filters in combination with the structure of porous activated carbon most efficiently reduces ozone in indoor air.

The international air purifier standard IEC60335-2-65:2010 requires that air purifiers do not generate excessive amounts of ozone. This is tested by running the unit in a closed chamber with the dimensions 3,0 x 3,5 x 2,5 meters for 24 hours. During the test the ozone concentration must not exceed 50ppb (parts per billion). All Blueair air models are tested and comply to IEC60335-2-65:2010. The standard is adopted by many countries around the world such as Taiwan, Korea, Japan and the countries in the European Union.

USA

CARB certification

The California Air Resource Board (CARB) requires that all air purifiers sold in the state of California are ARB-certified and tested in accordance with standard UL867 to ensure that they do not emit ozone in concentrations exceeding 50ppb. During the certification process the products undergo comprehensive tests in a closed chamber to measure ozone emissions. The tests go on for 8-hour long test periods, at high and low speed and with and without the filter installed.

Certified units are listed on the ARB website.

ARB certified products are identified by the ARB-mark printed on the product packaging with the text: Meets California ozone emissions limit: CARB certified

Energy Star

To earn the ENERGY STAR the unit’s ozone emission must meet the requirements of UL Standard 867, which limits the ozone emissions to ≤50 ppb (parts per million).

European Union

In order to CE-mark air purifiers, the ozone concentration must not exceed 50ppb in accordance with standard EN 60335-2-65.

China

Chinese air purifier standard GB 21551.3-2010 requires ozone concentrations not to exceed 0.1mg/m³.

Canada

Canadian air purifier standards C22.2 187-15 and CAN/CSA-E60335-2-65:11 requires ozone concentrations not to exceed 50ppb.

Sustainability is at the heart of the Blueair business model. In fact, to improve access to clean air for the next generation is the very reason we exist. To bring our purpose to life, we invest time and resources in developing best-in-class air purifiers that make the minimum impact on the environment, and by awareness-raising around the positive health effects of breathing clean air. Our air purifiers are made from responsibly sourced, recyclable materials and they are designed to consume a minimum of energy. Needless to say, we follow local and global voluntary programs and regulatory requirements to help our customers protect the environment. As a company we want to make a positive imprint on society. To improve the health and well-being of those most in need, our initiative CLEAN AIR FOR CHILDREN supports schools, nurseries, kindergartens and children’s hospitals around the world. We are proud to have improved access to clean air for over a million children around the world.

Blueair meets and exceeds regulatory and voluntary requirements related to sustainability.

ENERGY STAR is a globally recognized program of the U.S. Environmental Protection Agency (EPA). The program was developed to help consumers save money and to protect the environment through energy efficient products. Blueair was among the first air purifier manufacturers to earn the ENERGY STAR designation for all its models sold in the US and thanks to their high CADR, Blueair air purifiers significantly exceed the minimum ENERGY STAR requirements.

Blueair models sold in China and Korea meet local Energy Efficiency regulations. The regulations measure and grade the air purifier’s efficiency (CADR/W) and require the models to be labeled with the EER mark and grade.

All Blueair products sold in the European Union follow the Restriction of Hazardous Substances (ROHS) directive 2011/65/EU from the European Union. Each product is tested in order to make sure it does not contain any substances prohibited according to the directive. Amongst the prohibited substances are lead, mercury and cadmium.

ROHS requirements similar to those found in the EU also apply to air purifiers sold in China, Taiwan and the United Arab Emirates. Blueair complies to the ROHS requirements in these markets.

Blueair follows the Reach directive, EC1907/2006, Registration, Evaluation, Authorization and Restriction of Chemicals and the Waste Framework Directive, 2008/98/EC, that requires all manufacturers and importers of chemicals, including products, to register any use of Substances of Very High Concerns in concentrations exceeding 0,1% (weight over weight), to the European Union and the European Chemicals Agency. Blueair tests all developed products in order to ensure that no prohibited chemicals are used and that the concentrations do not exceed any set limits.

As a producer of household appliances, Blueair is responsible for the collection, recycling and recovery of the Blueair products that are placed on the EU market under the Waste Electrical and Electronic Equipment Directive (2012/19/EU). Blueair, directly or via local partners, cooperate with local recycling schemes to ensure that Blueair products can be responsibly collected and recycled.